The U.S. Attorney’s Office for the Southern District of Florida has launched a new Whistleblower Non-Prosecution Pilot Program. It reinforces the recent efforts of the Department of Justice Criminal Division’s new Corporate Whistleblower Awards Pilot Program.

The local pilot program offers non-prosecution agreements in exchange for the early and voluntary self-disclosures of criminal conduct. The Department’s pilot program offers financial rewards to a whistleblower who provides original and truthful information about corporate misconduct that results in a successful forfeiture.

Both pilot programs require the prompt disclosure of truthful and complete information.

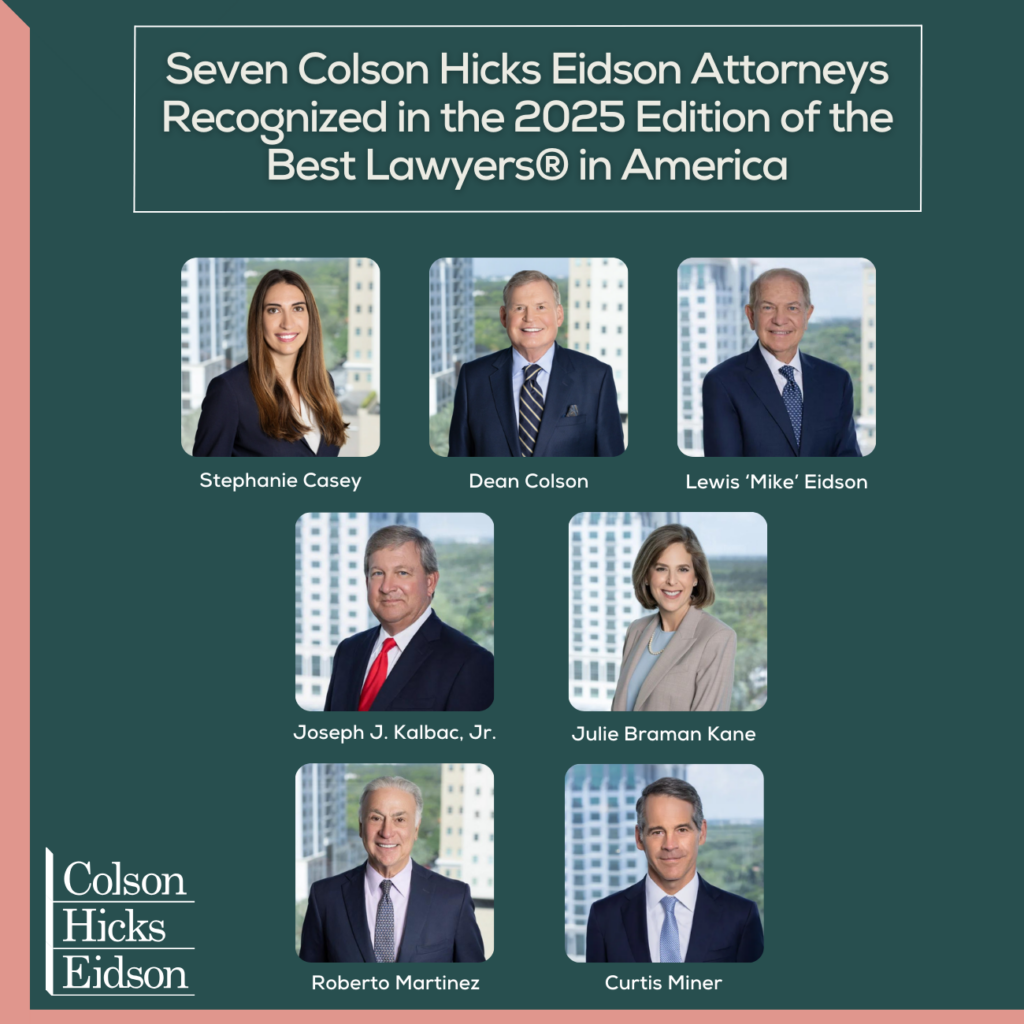

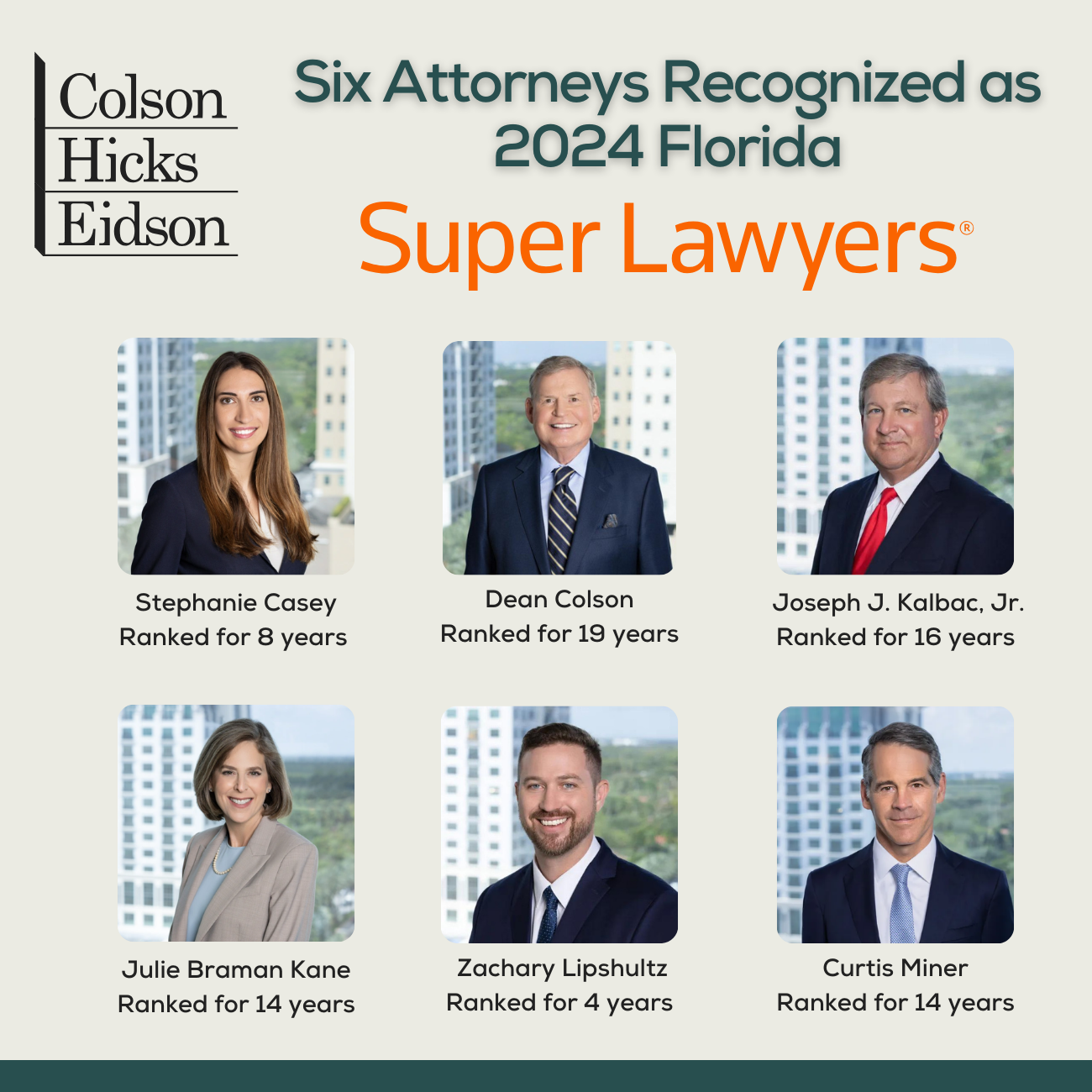

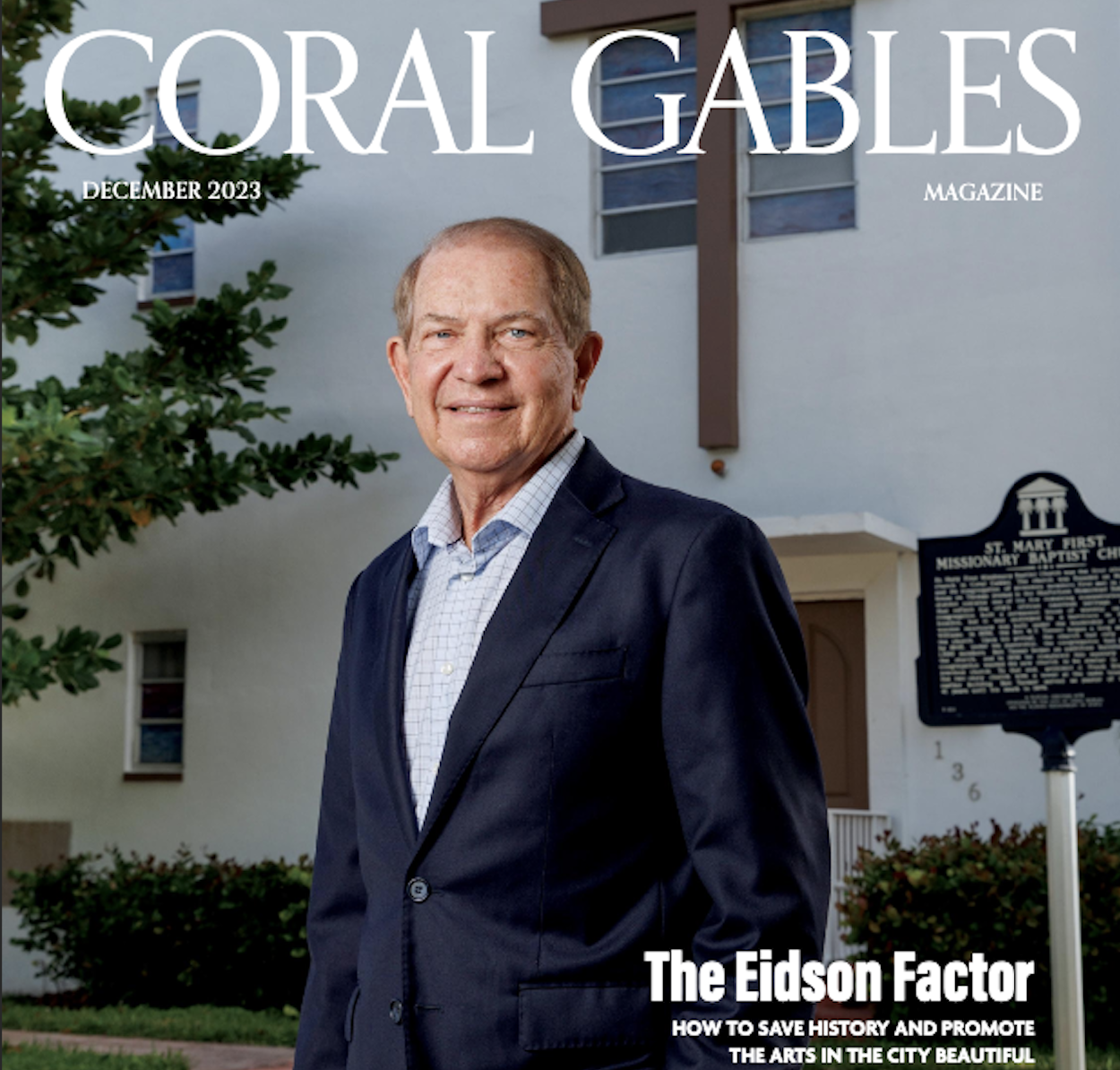

At Colson Hicks Eidson, our attorneys have advised and represented clients across the full range of internal investigations, government inquiries, enforcement actions, whistleblower actions, and civil and criminal trials. For further information, contact us at 305-476-7400 or info@colson.com.